Waterproof textiles

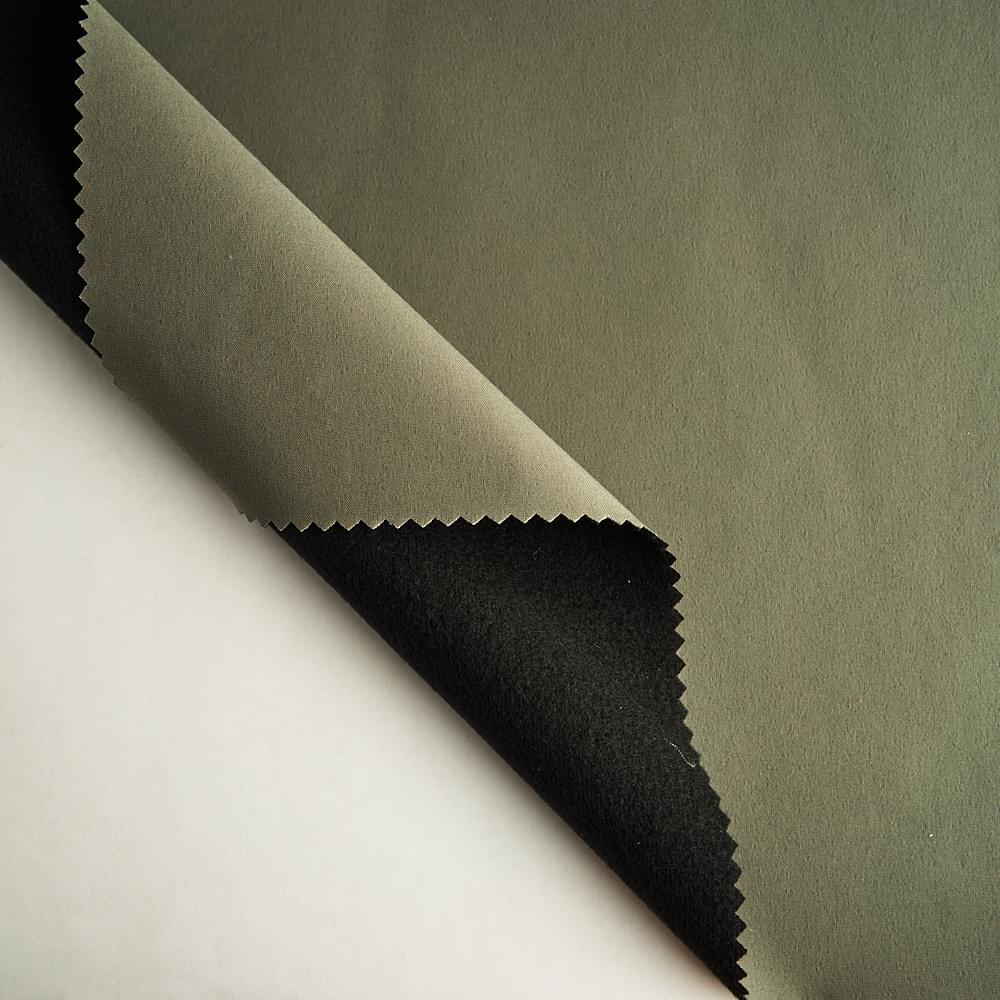

Inmed produces two- and three-layer waterproof textiles on modern equipment, by hot-melt dot lamination technology. Finished material undergoes quality control on three key parameters: waterproofness, breathability, and wind resistance.

You can see our testing equipment on the page about our laboratory - Laboratory.

1 / 7

Filter

Waterproofness

Breathability

Found by filters: 61

Total products: 61

1 / 7